rdc-03

rdc-02

rdc-04

rdc-05

rdc-01

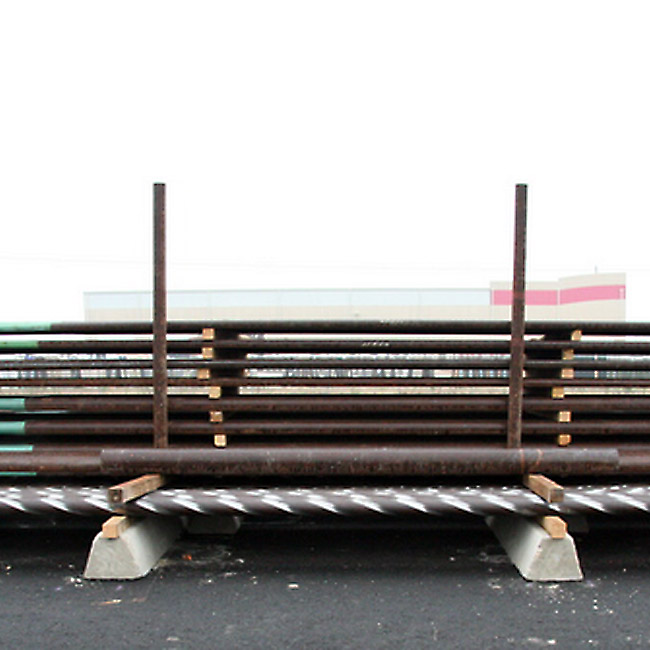

Technical Specs

- • Made of modified AISI 4145H chromium molybdenum alloy steel.

- • Bars are full-length heat treated and water quenched to obtain ASTM A-370 mechanical properties.

- • To ensure close tolerance bores, all drill collars bars are trepanned then drifted to API specifications.

- • Bar surface finish is "as rolled" which is original mill finish (silver color optional)

- • Full mechanical and chemical mill test certifications are supplied with all our drill collars making each joint completely traceable.

- • Manufactured in Houston, Texas, United States of America.

Connections

- • All connections are precision-machined to API specifications and quality-control inspected.

- • API relief groove pin and bore back box stress reliefs feature are available on request.

- • Thread roots are cold-rolled to offer a greater resistance to fatigue.

- • All connections are chemically treated to produce a surface finish that minimizes galling during makeup.

- • Thread protectors are included on all joints.

Spiral Drill Collars

Why spiral Drill Collars? The spiral cut is added to a drill collar to prevent the possibility of wall-sticking by reducing the wall contact between the drill collar and the hole wall.

Where is the spiriling done on the drill collar? The box end of the spiral drill collars is left uncut from 18" to 24", and the pin end is left uncut 12" to 20" from the shoulder.

For ordering and quotations, please sepecify:

1. Outside diameter, bore and length.

2. Size and type of connection: each end of collar and joint features.

3. Slick or spiral.

4. Other special feature: fishing neck elevator, slip recess and/or hard banding.